According to a recent US study, only 9% of people manage to achieve their yearly resolutions.

In the current context, which is still pandemic with COVID-19, variants and increasing cases, there is every reason to believe that resolutions in the various sectors of activity must include the modernization of processes.

The world of textiles and clothing is no exception.

Judged to be the second biggest polluter on the planet, it was not until 1 January 2022 that the AGEC law was implemented in France so that brands could no longer destroy their unsold goods.

Since the law was enacted, various positions have been developed in companies and brands have implemented different recycling policies. The use of recycled materials is becoming the norm. Feathers, which are a by-product of the food industry, are being replaced by fake feathers, just as fur is being replaced by fake fur.

The recent rise and influence of platforms such as Vestiaire Collective (France) or Vinted (Lithuania) not only reflects a desire to consume differently, “by making the second choice the first choice”, but also reflects an industry that must evolve upstream.

The world is changing, we often hear. So does fashion, influenced by new trends and by the relationship to oneself. Nowadays, putting together a clothing collection has to take into account many more factors than it did 10 years ago.

Indeed, if good looks, colors, and price used to be enough to launch marketing plans to massively distribute a brand, it is different today.

The new generations of buyers want inclusion, to think about animal welfare, for raw materials to have the lowest possible carbon footprint… and for products to fit them well, whatever their morphotype. For this last point, it is the pattern makers who are the actors of change.

This profession, which is generally perceived as a person in front of a wooden mannequin, a pair of scissors, needles and who assembles scattered pieces of fabric to put the garment together, is at the heart of the potential evolution of fashion.

The profession of pattern maker in the textile and clothing industry relies on different programs and tools. Gerber and Lectra, until Lectra’s takeover of Gerber Technology, were the main programs used to create the patterns and then cut the rolls of fabric so that the product could be born.

With the environmental awareness of society, it has become necessary to find alternatives to reduce the number of samples or collection pieces. CLO3D, Solutions4Fashion, Browzwear, Optitex … are partly responding to this problem and different industrial players are increasing the number of workstations using 3D technologies to reduce material consumption by allowing decision-making based on 3D rendering.

Nevertheless, during production launches, it is necessary to take into account the morphology of customers and their ages so that the products developed fit them well.

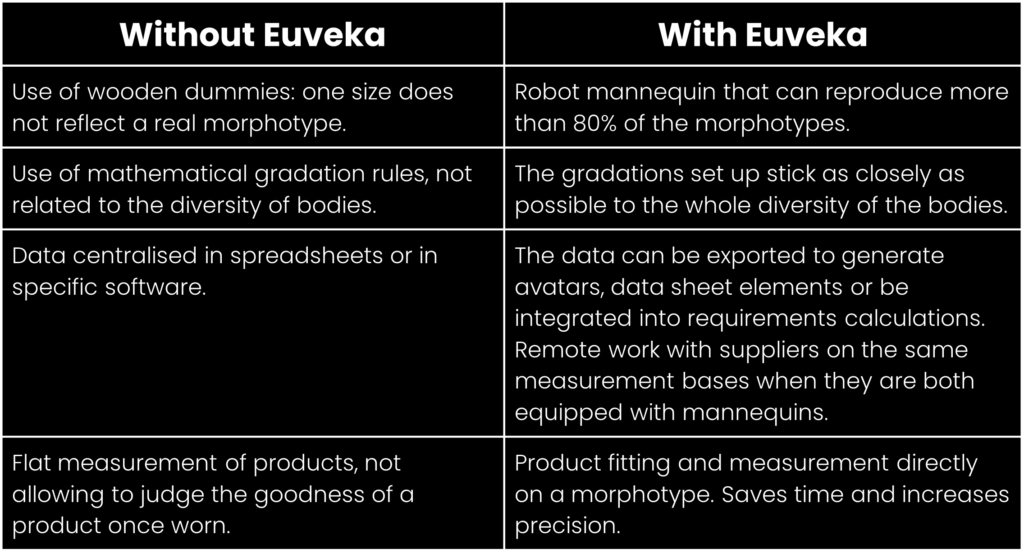

Equipped with the Euveka solution and the associated software, the model makers can test and appreciate the fit and the rendering of the products being developed on all size grids and all fits. Through the use of the Mimeo software, allowing the adaptation of the robot mannequin in less than 90 seconds from one morphotype to another, the model makers can work more efficiently.

Fashion designers, at the heart of this change, can accompany the movement towards a more ethical, more inclusive, more environmentally friendly and above all, more customer-friendly fashion.

The fashion of sustainable development must become the sustainable development of fashion.

#Modelist #Fashion #Euveka #Ecology

About Euveka

Founded in France in 2011, Euveka produces and distributes a “phygital” solution of connected mannequins that reproduce sizes and morphotypes to encompass as much as possible the diversity of consumers’ bodies.

Euveka’s mission is to enable brands to reduce the amount of unsold merchandise and customer returns due to “poor fit”, thus engaging the entire value chain towards a more sustainable and inclusive fashion.

From 1 January 2022, non-food waste should start to be reduced.

Indeed, following the enactment of the Anti-Waste and Circular Economy Law (AGEC to its friends), the entire value and supply chain will have to reduce waste. Specifically, the law aims to “oblige producers, importers and distributors to re-use, re-purpose or recycle unsold non-food products”.

Every year, between 10,000 and 20,000 tonnes of new textile products are destroyed in France. This is equivalent to the weight of one to two Eiffel Towers. Worldwide, the textile industry emits 1.2 billion tonnes of greenhouse gases each year, or 2% of global greenhouse gas emissions.

The nature of this law is in line with the times: the need to consume less and better, to reuse in order not to generate an additional carbon footprint, etc. But it is important to understand to whom this law will apply and what penalties will be incurred.

Which sectors are affected by this law?

– Electrical products

– Electronic products

– Batteries

– Textiles

– Furniture

– Ink cartridges

– Hygiene and childcare products

– Food storage and cooking equipment

– Early learning products

– Leisure products

– Books

– School supplies

There are many producers of these different consumer goods whose supply chains are often long, dispersed and CO2-generating.

Although electrical and electronic products and everything related to technology are polluting and pose waste treatment problems, the fact remains that the industry that consumes the most natural resources and pollutes the most is the textile industry.

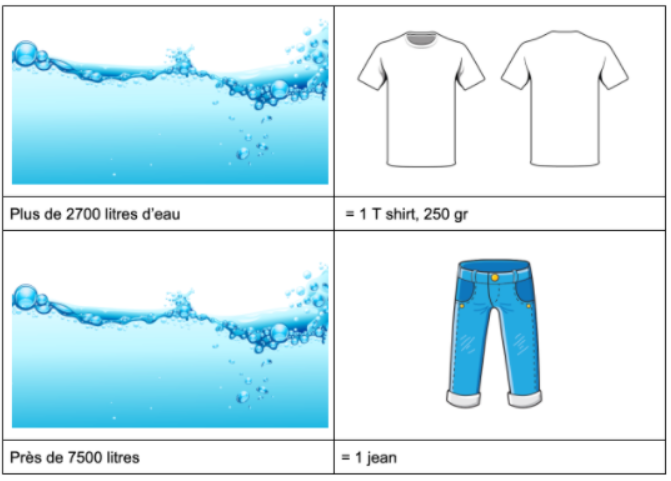

The textile and clothing sector is even the second most polluting industry and generates more than 1,200 billion tonnes of CO2 per year. To grow natural materials, to dye them, or to produce synthetic products, astronomical quantities of water are needed.

If we consider that a human being must drink between 1.5 and 2 litres of water per day, wearing jeans and a T-shirt represents consumption of 5100 days to 6800 days, we end up with human consumption of about 15 years on average!

The clothing industry needs new performance indicators, such as those set up by Fairlymade for example.

Vestiaire Collective and Vinted are tackling the issue of the lifespan or number of uses of a garment before it ends up in the back of a wardrobe before being thrown away.

However, a whole range of clothing is not taken into account: The clothes that are produced, put on the shelf, marketed, but never sold. In addition to the direct and indirect costs, it is the environmental impact that must also be taken into account with the thousands of litres of water and the associated CO2 to develop trousers, skirts, blouses, etc. that will not find a buyer.

Apart from going through 3D developments that can let consumers assess whether such and such a pattern, such and such a colour, will have any hope of commercial success, it is time to tackle a major problem head-on!

And this problem is that of morphology, of “fit”.

For a long time, a few mathematical rules were enough to extrapolate and what was not sold at the normal price tended to be sold at the discounted price, and in the worst case, the items were put on clearance. With AGEC, this is now a thing of the past and brands will have much to gain by using new technologies to assist them in the sizing and grading of their garments. This is EUVEKA’s core mission.

How does Euveka technology prevent the creation of future unsold items?

This preventive solution implemented upstream of the production process, allows better targeting of the market thanks to its data collection system.

The mannequin robot makes it possible to reproduce a fitting experience as close as possible to morphological reality.

Being able to collect information before the fitting on a mannequin and on various other morphologies is an undeniable asset to verify the fit of the garment before launching thousands of units that do not correspond to the morphologies of the target market and that will either be returned or unsold.

Euveka’s technology prevents production defects and allows brands to better fit and sell to all body types.

In case of infringement, what do companies risk?

15,000 EURO per breach and per legal person.

While awareness of environmental stewardship and the need to consume natural resources more efficiently is healthy, the fact remains that most mid-and high-end brands that have embarked on recycling their products have done so from 10 February 2020, when the AGEC law was enacted.

Unsold clothing accounts for 40% of unsold goods and has the greatest impact in terms of pollution and waste of natural resources.

Some brands, such as Wuxly Movement, a Canadian brand, even offered to take back used down jackets, or those still in condition, in order to establish a credit note for the purchase of their product, which is “cruelty-free”, without feathers or fur, in order to participate in a fashion that is less aggressive towards animal species. This brand also stands out for its commitment to recycling raw materials in order to have the lowest possible carbon footprint.

In Europe, and in France in particular, the objects and clothes that can no longer be disposed of must be donated to charities.

While we can be pleased with this implementation of solidarity at full speed, taking into account morphotypes from the design phase of products is an option that will also make it possible, along with reuse and recycling, to reduce the waste of natural resources.

To find out more about the AGEC, please visit the Ministry of Ecology website.

For decades, models were constructed from wooden mannequins for Ready-to-Wear, whereas Made-to-Measure was based on the actual proportions of a human body, in this case, the buyers.

The advantages of Made-to-Measure are numerous, ranging from fit to the selection of materials with the stylist to arrive at a unique piece that gives complete satisfaction to the customer, who has spent time with a professional to acquire an optimal garment that will last longer.

In the ready-to-wear sector, for years, it was a matter of going through measurement tables, statistical gradations updated every ten years.

With the help of mannequins and the accumulated experience of model makers, fashion has continued to spread across borders to new markets, with different morphologies, but without always taking them into account.

In addition, the rapid growth of the world’s population and changes in eating habits have contributed to the fact that these pre-established models no longer correspond to the morphologies of the buyers. Over the past 20 years, the arrival and development of fast fashion has resulted in buyers being drowned in a multitude of gradations, each reflecting a different idea of the customer. The number of garments produced and never worn has continued to grow due to this broken link between “who is my customer” and “what can/wants to wear my customer”.

The result is the ecological impact we are currently experiencing, which will be the subject of a separate article.

To make fashion fit you so well, the use of morphological data has become a real necessity.

In the age of the Metaverse and 3D, all in a pandemic context, the robot mannequin reflects at least a triple desire:

All this is good, you may say, but what is a robot mannequin and how is it better than a classic mannequin?

It has special features that allow it to be adjusted to check sizes, prototypes in all gradations so that brands can perform beyond their base sizes, but also in all other morphologies allowing designers and pattern makers to do their work more efficiently.

The main features are as follows:

– Adjust the robot according to your grading rules. This is a “Lord of the Rings” mode where a dummy is used to govern them all.

– The dummy is available 24 hours a day and is a perfect alternative to cabin dummies which are not always available. The robot mannequin ensures that all your products can be tested and their measurements verified in a minimum of time.

– Thanks to its technology, the robot mannequin also allows you to reproduce the size of your other products and to ensure the consistency of the size and gradation grids, season after season.

– Finally, as with any high-tech solution, your data can be exported for analysis to highlight measurement discrepancies and identify garment flaws prior to production launch.

– From a brand’s perspective, this is a great way to improve sustainability and inclusion. And with the data collected, it is also an opportunity to reduce their logistics and production costs.

Whether it’s made of wood or covered in canvas, the wooden mannequin has satisfied generations of designers, and let’s be honest, it has a noble and solemn side. Nevertheless, the classic mannequin is what it is: static, non-adjustable and the main flaw is that it does not reflect a real human body. Like a statue, it embodies an idea of a body onto which different clothes can be fitted.

The development and testing of “size sets” on such mannequins contribute to the uselessness or impossibility of selling certain products. Indeed, as long as your body is within the norm and you remain in the most common sizes, you have a good chance of finding the right shoe, or rather the right shirt for your bust.

However, as soon as you move towards sizes such as XS or 3XL+, it often happens that the clothes don’t fit you, too tight, sleeves too long or too short, difficulty to close the buttons at the chest level… or simply, that the garment doesn’t fit you or doesn’t please you anymore once worn because you don’t like it.

At a time when facial recognition is becoming commonplace and digitization is going full steam ahead, it seems that producing sizes well is based more on a desire by brands and manufacturers to use modern tools than on a compulsion to develop solutions themselves.

The robot mannequin thus appears to be a means of responding to society’s evolutions and challenges.

Brands and distribution networks continue to expand worldwide and taking into account different morphologies is mandatory.

A poorly designed product is a product that will never be sold. It will nevertheless have been adjusted, produced and therefore consumed natural resources. Worse still, it will have been transported, placed in a shop… all to end up indefinitely in stock.

Outre l’impact économique, c’est aussi un large impact en termes environnementaux, et ces impacts sont supportés par les marques, les distributeurs et les consommateurs.

Disposer d’un robot mannequin permet aux marques de pouvoir exploiter les bibliothèques de données propres à Euveka. C’est alors aller au plus près des morphotypes de chaque cliente. C’est inclure les morphologies des femmes du monde entier pour faire en sorte que les produits de chaque taille soit achetables et portés plus longtemps. Le mannequin Euveka permet aussi une inclusivité de toutes les personnes travaillant sur les vêtements et de réduire la pénibilité grâce à la suspension intégrée. Aujourd’hui, plus que jamais, les marques peuvent faire que la mode vous aille bien.

Euveka est une société française disposant d’une technologie brevetée, de 8 ans de Recherche et Développement et dont l’objectif affirmé est de rapprocher les marques de leurs marchés grâce à son mannequin robot.

Don’t fit the garment on you, visualize your article at your morphology directly on the robot-mannequin!

Article

Jan 20 2022

Read articleArticle

Jan 20 2022

Read articleArticle

Jan 20 2022

Read articleInterview Vidéo

May 19 2021

Read articleProduct Video

Apr 15 2021

Read articleProduct Video

Mar 31 2021

Read article